Floating Roof Tank Earthing Strategies - Bypass conductors for lightning

10/24/2017

As an example, if the lightning strike hits a nearby stack. This can cause the charge in the tank walls to discharge rapidly. The trouble is, this leaves a ‘bound charge’ suspended in the product itself, which if the tank is not earthed (grounded) robustly, this can create a secondary arc. Igniting the vapours!

This highlights why lightning does NOT have to hit the tank itself to cause an explosion/fire.

Nearby strike

Reducing the Risk

Sparking shunts

Floating Roof Tank SHUNTS shown in the image above, have been used for many years as the default method to earth-out (ground) the roof to the tank wall.

Studies by the API (American Petroleum Institute) have shown these shunts often fail to provide the required contact between the roof and wall. They are prone to wear issues as well as being sensitive to tank deformation. Without a properly earthed roof, the risk of FIRE is very real.

So, knowing shunts are not the complete answer for Floating Roof Tanks; especially for the larger tanks. Good engineers will install secondary bypass conductors to close-out the risk of the shunts not performing to prevent arcing at the roof/shell interface. But it doesn't stop there!

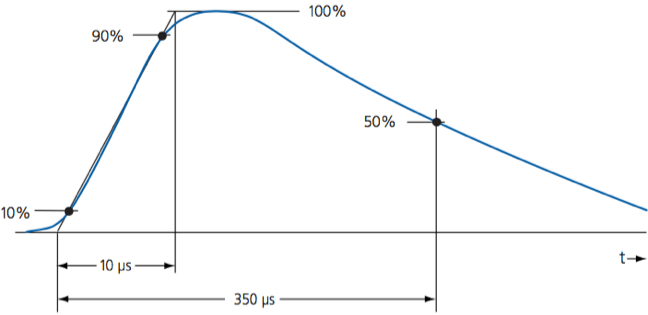

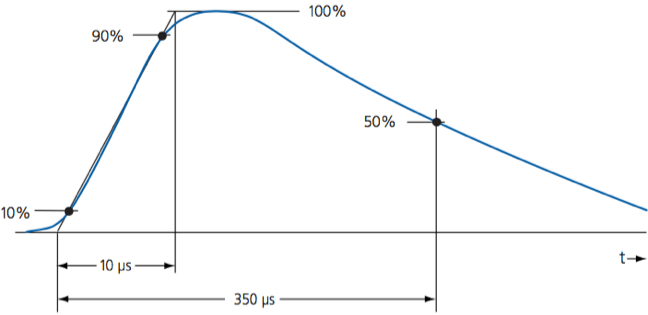

10-350 lightning waveform - BS EN 62305

Lightning has a complex personality. It is made up of multiple frequencies from DC to Megahertz (MHz). Thus, the lightning current can in turn exhibit multiple behaviours or responses, unlike a single power frequency related fault. The average energy released in a single lightning flash to the ground is 55 kWh. A significant amount of energy by modern generation standards.

According to IEC 62305, Lightning current magnitudes for a Class I, lightning protection level (LPL) are considered and designed to withstand 200 kA. A feature of lightning currents is the fact that most of this energy is expended in only 100 to 300 microseconds and

that the lightning reaches peak current in a matter of microseconds, i.e. it manifests in the form of a ‘pulse’ (discharge).

Substantially reducing the risk of sustained arcs for the Floating Roof Tank requires a reliable, full-time, low impedance and low-resistance connection between the tank shell and roof. The low impedance is really desirable due to the higher frequency components of a lightning strike. The low resistance is necessary to 'mop-up' the lower frequencies efficiently until the discharge process (current flow) has finished. All this, regardless of the tank shell’s condition and geometry.

Option 1

One option is to rely on the tank shunts as the only protection measure. But as mentioned earlier, this carries a significant risk of failure when you most need it. Large tanks deform during high winds, i.e. in storms! Compromising how the shunts perform. Overtime, the shunts themselves take on deformation and effectively get stuck into positions that are simply not in contact with the shell. For every shunt not in contact with the shell equates to an increase of arcing and overloading the remaining shunts. No prizes for what can happen next!

Option 2

Supplement the shunts with a conventional direct cable connection from the shell wall to the roof. Although not an elegant, it does add a layer of mitigation by providing a low resistance connection, at least. The downside is the risk of cable-snagging and getting cut without anyone noticing until it's too late. Inspections of live tanks at high-level usually requires special breathing equipment and pre-planning as part of scheduled maintenance. Therefore, it could be months before a severed cable is noticed.

In addition, the cable is fixed length, therefore, fixed impedance regardless of roof position. This impedance can be quite high if not carefully considered. The low impedance bond is particularly important if the tank suffers a direct strike where the energy is discharged more locally, and the higher frequency component of lightning plays a more significant role.

Option 3

Option three adds another layer on from the previous options by connecting the wall-roof directly with a low-resistance-low-impedance conductor. In real-life, these retractable conductors are distributed around the tank perimeter shell at equidistant spacings to share the lightning current load evenly.

FRT bypass conductor RGA

Bypass conductors compliant to API RP 545 are an incredibly simple way of achieving a robust electrically continuous path between the floating roof and tank wall 100% of the time. This keeps both the wall and the roof at the same potential, without the risk of a cable being severed, or shunts failing.

This option gives you the peace of mind that the contents of your tank will not ignite due to lightning induced issues. Although, it has to be noted that the correct installation of the Bypass conductors is critical. Get this bit wrong, and any benefit from the retractable conductors evaporates - so it is advisable to get the units installed (preloaded) correctly from the outset by a competent 'trained' engineering team.

If you are at the point of reconsidering your existing shunt system… Why not email us so we can discuss the next steps…